By leveraging 3D printing, you can create custom greenhouse components tailored precisely to your needs. This technology allows you to optimize designs for better airflow, light distribution, and structural strength. You can also produce intricate parts like ventilation systems and integrated irrigation channels efficiently. Using eco-friendly materials, this approach promotes sustainability and reduces waste. Keep exploring to discover how these innovations can transform your greenhouse and enhance your agricultural practices.

Key Takeaways

- Enables tailored, precise components like vents, supports, and irrigation channels to meet specific greenhouse needs.

- Uses biodegradable or recycled materials to promote eco-friendly and sustainable construction practices.

- Facilitates complex geometries for optimized airflow, lighting, and climate control within the greenhouse.

- Allows rapid on-demand production, reducing waste, inventory, and enabling quick adaptation to evolving requirements.

- Supports continuous innovation through customizable designs, integrated features, and eco-conscious material choices.

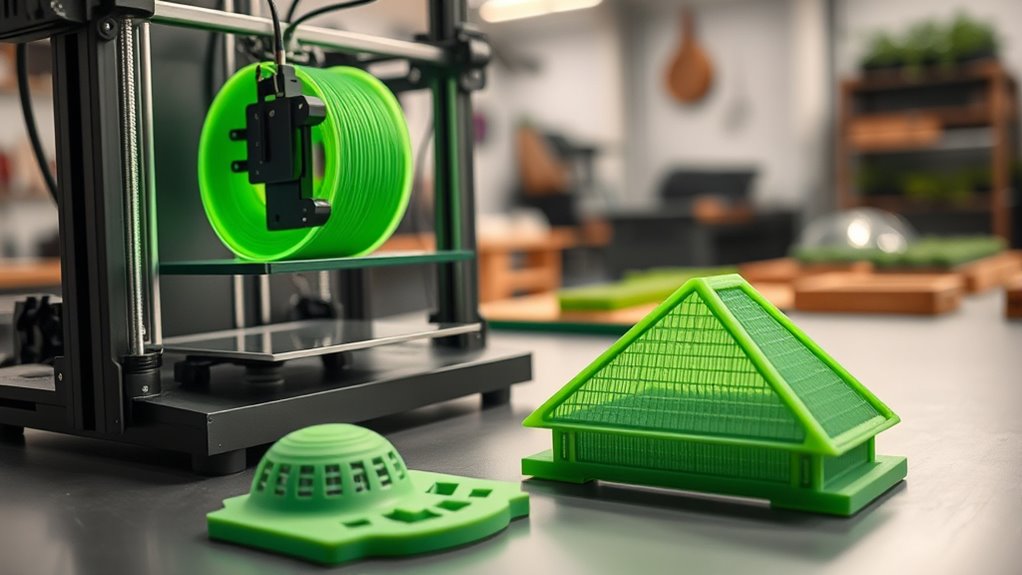

3D printing is revolutionizing the way greenhouses are built by allowing for the rapid and cost-effective production of custom components. This technology opens doors to innovative construction methods, especially when it comes to integrating sustainable materials and optimizing designs. When you choose sustainable materials for 3D printing greenhouse components, you’re making a conscious effort to reduce environmental impact. Biodegradable plastics, recycled filaments, and bio-based composites are now readily available options that guarantee your greenhouse construction aligns with eco-friendly principles. Using these materials not only minimizes waste but also promotes a circular economy, which is vital for sustainable agriculture and construction practices.

Design optimization plays a key role in maximizing the benefits of 3D printing for greenhouses. Instead of relying on off-the-shelf parts, you can tailor components precisely to your needs, reducing material waste and improving structural integrity. For example, you can design custom brackets, vents, or support structures that are lightweight yet sturdy, thanks to the flexibility of digital modeling and additive manufacturing. This level of customization means you get components that fit perfectly, eliminating the need for modifications or adjustments during assembly, saving you both time and resources.

Tailor components precisely to your needs, reducing waste and enhancing structural integrity with digital modeling and additive manufacturing.

Furthermore, 3D printing allows you to experiment with complex geometries that traditional manufacturing methods struggle to produce. This capability enables you to create intricate ventilation systems or shading devices that optimize airflow and light distribution within the greenhouse. By integrating design optimization, you guarantee that each component serves a specific function efficiently, contributing to better climate control and plant health. This precision also means you can incorporate features like integrated channels for irrigation or wiring, streamlining maintenance and reducing clutter.

The combination of sustainable materials and design optimization translates into a more resilient, eco-friendly greenhouse structure. With 3D printing, you’re empowered to make thoughtful choices about material use and component design, which ultimately leads to a more sustainable operation. You can produce parts on demand, reducing inventory and waste, and adapt your designs quickly as your needs evolve. This agility allows for continuous improvement and innovation, pushing the boundaries of traditional greenhouse construction. Overall, 3D printing offers a smarter, greener way to build greenhouses—one that emphasizes sustainability, efficiency, and customization at every step. Incorporating risk-taking into your design process can lead to breakthrough innovations that further enhance your greenhouse’s performance and sustainability.

Frequently Asked Questions

What Are the Environmental Impacts of 3D Printing Greenhouse Parts?

The environmental impacts of 3D printing greenhouse parts include benefits like sustainable manufacturing and material recyclability. You can reduce waste by reusing filament and designing parts for minimal material use. However, you should be aware of energy consumption during printing and the potential release of emissions from certain plastics. Overall, it offers a greener approach, especially when you choose eco-friendly materials and optimize your process for sustainability.

How Cost-Effective Is 3D Printing for Large-Scale Greenhouse Production?

Imagine a bustling workshop where speed and savings dance together—3D printing can be quite cost-effective for large-scale greenhouse parts. You’ll notice a favorable cost comparison, especially when producing complex pieces that traditional methods struggle with. Plus, manufacturing speed accelerates, allowing you to meet tight schedules. While initial investments are higher, ongoing costs drop, making this approach a smart choice for scalable, innovative greenhouse projects.

Can 3D Printed Materials Withstand Extreme Weather Conditions?

Yes, 3D printed materials can withstand extreme weather conditions, especially when you choose durable materials like ABS or PETG. Modern printing technologies, such as FDM and resin printing, improve material durability by ensuring strong layer adhesion and resistance to UV, moisture, and temperature fluctuations. By selecting the right materials and advanced printing techniques, you can create greenhouse components that hold up well against harsh environmental factors.

What Is the Typical Lifespan of 3D Printed Greenhouse Components?

Think of your 3D printed greenhouse components as sturdy as ancient stone bridges, lasting several years with proper care. Typically, their lifespan depends on material durability, ranging from 3 to 7 years, but exposure to harsh weather can shorten this. Regular maintenance reduces wear and tear, ensuring your components withstand the elements longer. With thoughtful upkeep, you can enjoy a resilient structure that supports your green thumb for years to come.

Are There Any Safety Concerns With 3D Printed Greenhouse Materials?

You should be aware of safety concerns with 3D printed greenhouse materials, especially regarding material toxicity and fire hazards. Some plastics may release harmful fumes if heated excessively or degrade over time, posing health risks. Always choose non-toxic, heat-resistant materials, and guarantee proper ventilation. Additionally, avoid using flammable plastics near heat sources, and follow manufacturer guidelines to minimize fire risks and keep your greenhouse safe.

Conclusion

Imagine turning your greenhouse dreams into reality with 3D printing. By crafting custom components tailored to your needs, you can optimize space, improve durability, and reduce costs. Think of your greenhouse as a thriving garden of innovation, where each printed piece fits perfectly, like a puzzle piece finally finding its place. Embrace this technology, and watch your green oasis flourish, rooted in creativity and precision that transforms your gardening experience forever.